|

9-15E BLOCK MAKING MACHINE

Eleven points of Noah block machine

1. We adopts Germany blocks machine advanced technology. The machines are very heavy which adopts the thick Rectangular square steel. The Weight is beyond the domestic same models 30%. The vibration table is 486MM height to the ground with low center of gravity. It makes sure the 90% aftershock can be led to the ground directly. So it can lengthen the lifespan of the machines.

2. High vibration frequency. We adopt two hydraulic motors to transit. There are two eccentric shafts but not eccentric blocks in the vibration box. The eccentric axis runs more than 4500 turns/minute . It can make the concrete liquefied in three seconds with high excitation force. With this unique design has following advantage.

A. With high capacity. the blocks can be formed quickly and it is 15-16 seconds/mould.

B. The aggregates can distributes equality. It can improve the density and intensityofthe blocks.

C. With the same cement our machine can produce high density blocks. That’s to say to produce the high density blocks we only use less cement. It can reduce the cost. For example it can reduce 0.05kg/pc and it will reduce 750tons cement and reduce US$50000.00(China markets .

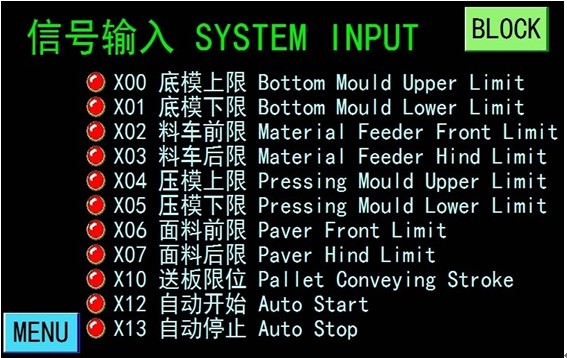

3.We adopts imported computer control system. You can adjust the technical number by touch screen. It has input and output device with man-machine.

4. The computer control system can lock itself. If the former action is not OK and the later action can not be done. It avoids the damage of the machine for the mistake action. It realize the far distance fault diagnosis.

5. The guide post is with deepen and hard chrome plate. Guide post is with extra durable copper bush. It can produce good blocks with less vein. We give six years guarantee of this guide post.

6. We adopts reciprocating vibrating screen forced feeding device. It can produce less than 20mm thickness. It can distribute material equality and quickly with high capacity.

7. Synchronism better. It is with synchronism gear in the pressed mould and lower mould. It can reduce the rerror +1MM with pressed head and demould.

8. multi-functional. It can produce hollow blocks, bricks and curbstone, color paver (with color machine device) and grass planting and interlock paver and so on

9. Vibration pressure separation technology

The vibration support plate, and at the same time, the deputy head, match damping rubber pad, thoroughly deaden vibration pressure interference

10.The variable frequency technology, makes the equipment operation is stable, and the saving energy save electricity, protect the motor

| QT9-15E PRODUCTION CAPACITY |

| SPEC. |

Block

390*190*190 71Pcs/m³ |

Block

390*100*190 135Pcs/m³ |

Rectangular 200*100*60 50Pcs/m² |

I Shape 200*165*60 30Pcs/m² |

S Paver

225*112.5*60 40Pcs/m² |

Porous Brick

240*115*90 402Pcs/m³ |

SolidBrick

240*115*53 683Pcs/m³ |

|

Code |

|

|

|

|

|

|

|

| Pcs/Pallet |

7.5 |

12 |

27 |

15 |

21 |

20 |

40 |

| Pcs/Hour |

1350 |

2160 |

4860 |

2700 |

3780 |

3600 |

7200 |

| Pcs/8 Hour |

10800 |

17280 |

38880 |

21600 |

30240 |

28800 |

57600 |

| Year(300day) |

45634m³ |

38400m³ |

233280m² |

213861m² |

229671m² |

8640000Pcs |

17280000Pcs |

| QT9-15E TECHNICAL DATA |

| Overall Dimensions |

6800*4150*2900(mm) |

| Pallet Size(mm) |

1100*700*25(Bamboo) |

| Machine Weight |

11100kg |

| The Frequency Of Vibrate |

50-90Hz |

| Max Excitation Force |

90KN |

| Cycle Time(s) |

15-20S |

| Installed Capacity(kw) |

32.8KW |

|